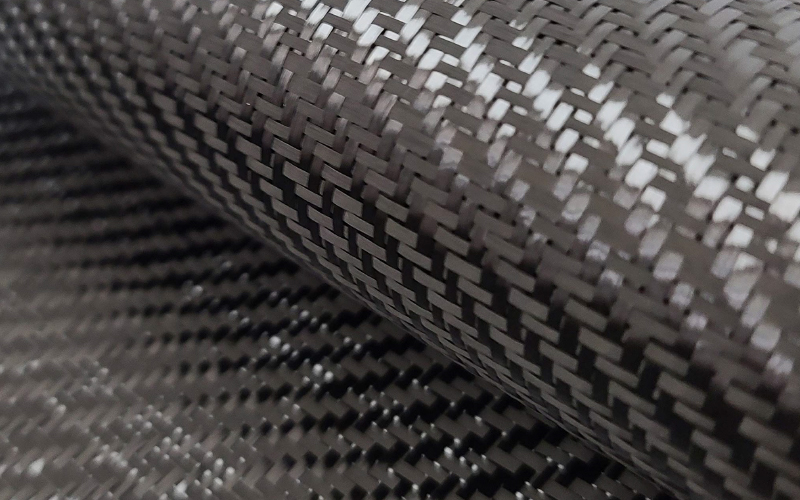

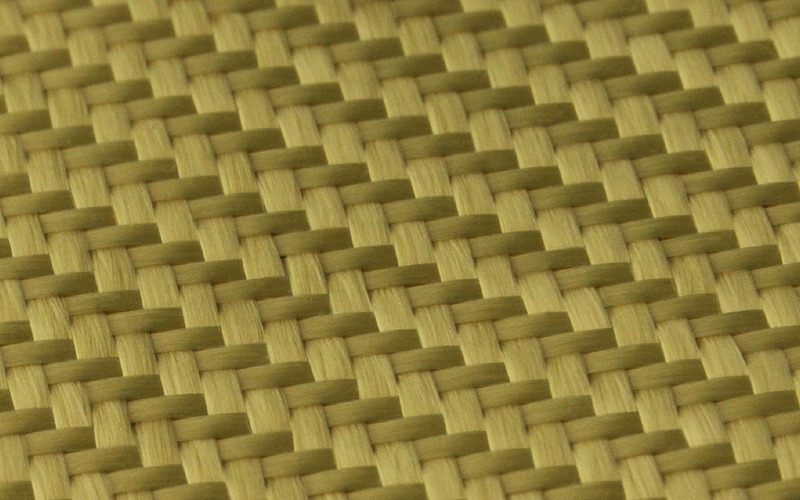

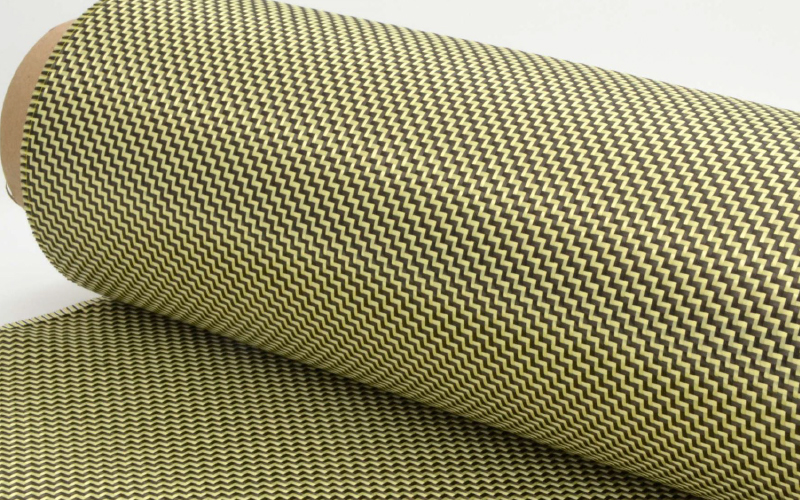

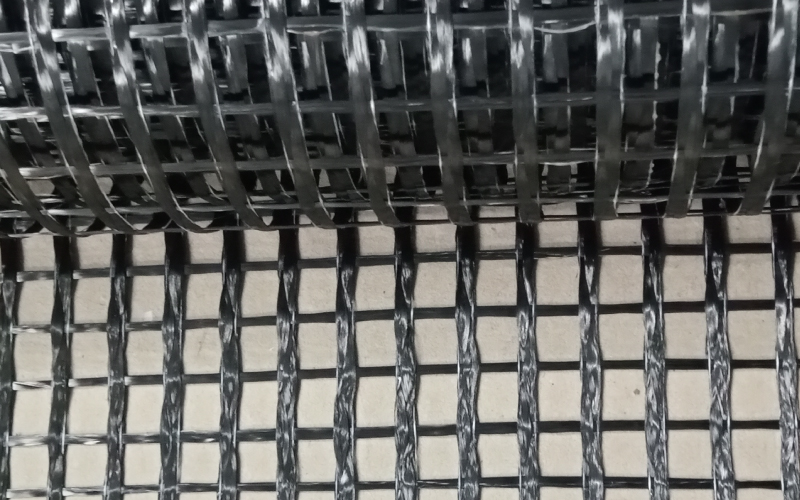

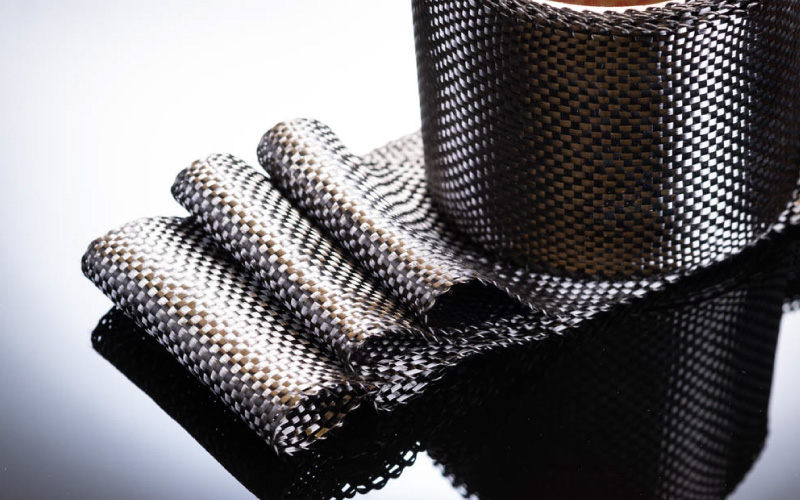

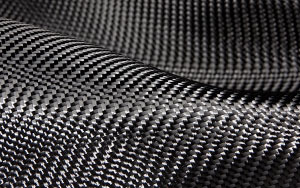

Fabric reinforcement is a fundamental technique in composite materials, revolutionizing the strength and versatility of structures across various industries. This process involves integrating layers of reinforcing fibers, such as glass, carbon, or aramid, into a matrix material, typically a resin. The resulting composite material exhibits enhanced mechanical properties, combining the strengths of both components.

Glass fiber reinforcements are valued for their affordability and versatility, making them prevalent in applications like boat hulls, automotive components, and construction materials. Carbon fiber reinforcements, known for their exceptional strength-to-weight ratio, find extensive use in aerospace, sports equipment, and high-performance automotive parts. Aramid fibers, such as Kevlar, are renowned for their impact resistance and are utilized in ballistic armor, aerospace applications, and other high-stress environments.

The fabric reinforcement process allows for customization of the composite’s mechanical properties by varying fiber types, orientations, and layering sequences. This versatility empowers engineers and designers to tailor materials according to specific application requirements, ensuring optimal strength, stiffness, and durability.

In construction, fabric reinforcements are used to reinforce concrete, providing tensile strength and minimizing cracking. In the aerospace industry, they form the backbone of lightweight yet robust aircraft components. In automotive manufacturing, fabric reinforcements contribute to the production of lightweight, fuel-efficient vehicles.

Whether in boats, aircraft, automobiles, or even consumer goods, fabric reinforcements play a pivotal role in advancing material science, enabling the creation of structures that are stronger, lighter, and more durable than traditional materials alone.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries. And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)

And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)