“Versatility Unleashed: Carbon Fiber’s Impact Across Industries”

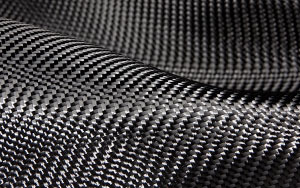

Carbon fiber has revolutionized various markets with its exceptional properties, becoming a sought-after material in industries worldwide.The automotive sector benefits from carbon fiber’s weight reduction capabilities, improving fuel efficiency, and optimizing performance in high-performance vehicles. Sports and leisure industries harness its strength-to-weight ratio in equipment such as bicycles, golf clubs, and tennis rackets, providing athletes with a competitive edge.

In renewable energy, carbon fiber plays a pivotal role in wind energy applications, where it is used to manufacture turbine blades, maximizing energy output.

The marine industry utilizes carbon fiber for boat hulls and components, enhancing durability and fuel efficiency. Medical advancements include the use of carbon fiber in prosthetics and orthopedic implants, offering lightweight solutions with high strength. The construction sector benefits from carbon fiber-reinforced polymers, adding strength to structures without the weight of traditional materials.

CONSTRUCTIONS

In the construction industry, carbon fiber has become a game-changer due to its remarkable properties. Widely employed as a reinforcement material, carbon fiber enhances the strength and durability of structures, especially in critical areas like seismic retrofitting and the reinforcement of concrete elements. Its exceptional tensile strength and lightweight nature make it an ideal choice for creating resilient and sustainable buildings.

Carbon fiber-reinforced composites are increasingly utilized in bridge construction, offering reduced weight without compromising structural integrity. This not only enhances the lifespan of bridges but also contributes to the overall efficiency of infrastructure projects. Additionally, carbon fiber enables innovative architectural designs, allowing for the construction of aesthetically pleasing structures that are not only visually appealing but also boast superior strength and longevity.

AUTOMOTIVE

WIND ENERGY

Carbon fiber has emerged as a pivotal material in the wind energy sector, playing a crucial role in the construction of turbine blades. Renowned for its high strength, low weight, and corrosion resistance, carbon fiber ensures the efficiency and longevity of wind turbines. Its unique properties enable the production of longer and lighter blades, maximizing energy capture and optimizing the performance of wind farms.

The exceptional fatigue resistance of carbon fiber makes it particularly well-suited for enduring the cyclic loading experienced by turbine blades in constantly changing wind conditions. As the demand for sustainable energy solutions grows, carbon fiber continues to be instrumental in enhancing the reliability and efficiency of wind energy systems, contributing to the global shift towards cleaner and more environmentally friendly power sources.

AGRICULTURE

MEDICAL DEVICES

In the realm of medical devices, carbon fiber has become a transformative material, particularly in orthopedics and prosthetics. Renowned for its high strength, lightweight nature, and biocompatibility, carbon fiber is utilized in the construction of orthopedic implants and prosthetic devices. Its ability to mimic the mechanical properties of natural bone makes it an ideal choice for creating durable and precisely engineered medical components.

The lightweight feature significantly contributes to patient comfort, while the strength ensures the longevity and reliability of the devices. Moreover, carbon fiber’s radiolucency is advantageous for medical imaging, allowing for clearer visibility during diagnostic procedures. As the medical industry continues to innovate, carbon fiber remains at the forefront, driving advancements in patient care through the development of high-performance and biocompatible medical devices.

SPORTS & MUSIC

F.A.Q.

Q: How can I place an order for customized textiles?

You can easily place a customized order by contacting our sales team through the provided channels on our website. We’ll work closely with you to meet your specific requirements.

Q: Do you offer samples of your products?

Yes, we provide samples to interested clients. Contact our sales team, and they will assist you in obtaining samples for evaluation.

Q: Are your technical textiles customizable in terms of specifications and dimensions?

Absolutely. We understand the importance of customization, and our technical textiles can be tailored to meet your specifications, including GSM, width, thickness, weave, and more.

Q: What sets your company apart from other textile manufacturers?

Our company stands out due to a legacy of excellence, a commitment to innovation, and a customer-centric approach. We combine traditional expertise with cutting-edge technology to deliver superior products.

Q: How do you ensure the quality of your textiles?

Quality assurance is paramount to us. We implement rigorous testing protocols at every stage of production, ensuring our textiles meet or exceed industry standards.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries. And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)

And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)