Resins

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries. Widely used in manufacturing, it solidifies through curing processes, offering durability and versatility in applications such as adhesives, coatings, and composite materials.

Epoxy System

Saturant

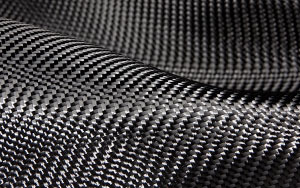

A saturant, in the context of composite materials, is a resinous substance used to impregnate and saturate reinforcing fibers, typically in the production of laminates. This viscous liquid, often epoxy-based, enhances the strength and cohesion of the composite structure. As it permeates the fibers, the saturant forms a solid matrix upon curing, reinforcing the material and providing excellent resistance to environmental factors. Saturants are crucial in manufacturing processes such as pultrusion and filament winding, ensuring a thorough bonding between fibers and resin, resulting in robust, lightweight, and high-performance composite products across various industries.

Primer

A primer, in the realm of coatings and adhesives, is a preparatory layer applied to a surface before the main coating to enhance adhesion and ensure a durable bond. Typically composed of resin and additives, primers create a receptive surface by promoting wetting and bonding between the substrate and the subsequent coating. They serve as a crucial interface, preventing issues such as corrosion, promoting paint adhesion, and improving overall coating performance. Whether applied in automotive finishes, construction materials, or industrial coatings, primers play a pivotal role in optimizing the longevity and efficacy of protective and decorative coatings on a wide range of surfaces.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries. And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)

And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)