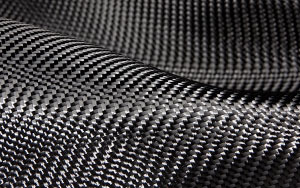

In recent years, carbon fiber composites have garnered significant attention and acclaim in the manufacturing industry, heralding a paradigm shift from traditional metals. This remarkable material, composed of intertwined carbon fibers embedded in a polymer matrix, has proven itself to be a game-changer, offering a host of advantages that position it as the future metal for manufacturing.

Unrivaled Strength-to-Weight Ratio: One of the key attributes that propels carbon fiber composites into the limelight is their unparalleled strength-to-weight ratio. Pound for pound, carbon fiber is stronger than steel, yet remarkably lightweight. This quality holds immense significance in industries such as aerospace and automotive, where reducing weight without compromising structural integrity is paramount for enhancing fuel efficiency and overall performance.

Versatility Across Industries: Carbon fiber’s versatility is another factor contributing to its ascent in the manufacturing hierarchy. Its applications span a multitude of industries, from aerospace and automotive to construction and sports equipment. As a replacement for metals, carbon fiber composites are reshaping the way we conceive and construct everything from aircraft components and vehicle structures to high-performance sporting gear.

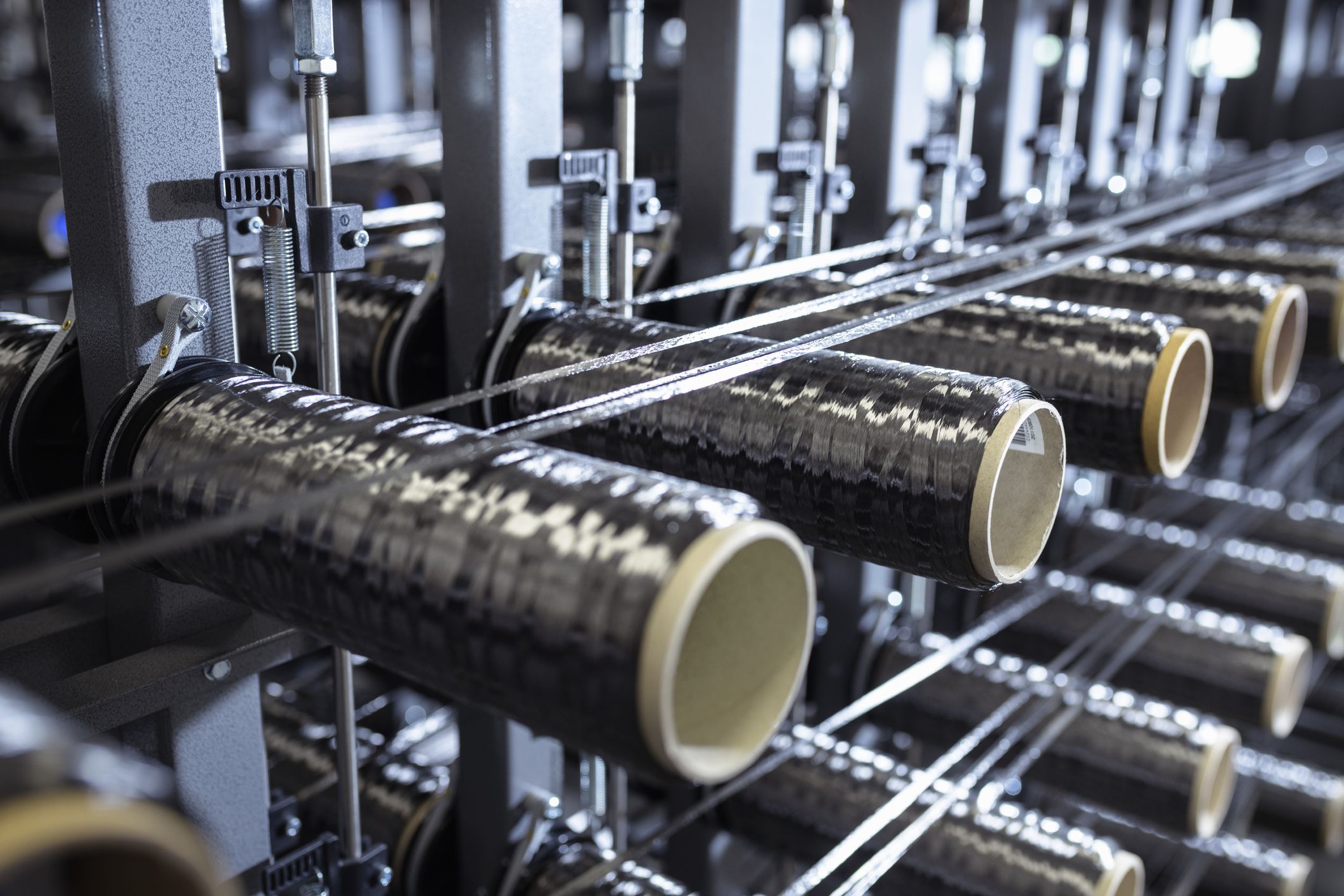

Innovations in Manufacturing Processes: The manufacturing landscape is witnessing a transformative evolution with advancements in carbon fiber composite production processes. Precision engineering and innovative manufacturing techniques are enabling the creation of complex structures that were once deemed challenging or impossible with traditional metals. As technology continues to evolve, we can anticipate even greater strides in the efficiency and scalability of carbon fiber manufacturing.

Sustainability and Environmental Impact: Beyond its mechanical prowess, carbon fiber composites align with the growing emphasis on sustainability. The production of carbon fiber involves significantly lower energy consumption compared to traditional metals, contributing to a reduced carbon footprint. As industries increasingly prioritize eco-friendly practices, carbon fiber emerges not only as a technological advancement but also as an environmentally responsible choice for manufacturers.

Challenges and Future Prospects: While the rise of carbon fiber composites is undeniable, challenges remain, including cost considerations and recycling processes. However, ongoing research and development are addressing these hurdles, paving the way for a future where carbon fiber could become more cost-effective and environmentally sustainable. As industries continue to adopt and adapt to this transformative material, the trajectory of carbon fiber composites as the future metal for manufacturing seems destined for greater heights.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries. And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)

And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)