The wind energy sector is on the brink of a transformative shift, thanks to groundbreaking advancements in the development of new carbon fiber for wind turbine blades. This cutting-edge material holds the promise of not only improving the performance of wind turbines but also offering significant cost benefits. As the demand for renewable energy continues to rise, this innovation is poised to play a pivotal role in reshaping the landscape of sustainable power generation.

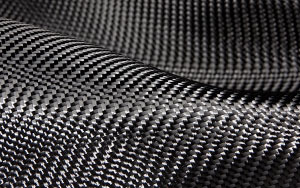

Enhancing Performance with Advanced Materials: Traditional wind turbine blades are typically constructed from fiberglass reinforced with polyester or epoxy resin. The introduction of carbon fiber into this equation brings a remarkable leap in performance. Carbon fiber’s high strength, low weight, and excellent fatigue resistance make it an ideal candidate for wind turbine applications. These characteristics translate into more efficient and durable blades that can withstand the stresses of continuous operation.

Cost-Efficiency through Lightweight Design: One of the key advantages of incorporating new carbon fiber into wind turbine blades lies in its lightweight nature. Lighter blades reduce the load on other turbine components and enable more efficient energy capture. Additionally, the lightweight design contributes to easier transportation, installation, and maintenance. While carbon fiber has historically been associated with higher costs, advancements in manufacturing processes and increased demand are driving down prices, making it a more cost-effective option for the wind energy industry.

Durability in Challenging Environments: Wind turbines are often subjected to harsh environmental conditions, including strong winds and varying temperatures. The durability of carbon fiber makes it well-suited to withstand these challenges. Carbon fiber-reinforced turbine blades have the potential to offer a longer lifespan and reduced maintenance requirements, further bolstering the economic viability of wind energy projects.

Environmental Impact and Sustainability: In addition to its performance benefits, the use of new carbon fiber aligns with the broader push for sustainable energy solutions. Carbon fiber’s manufacturing processes are becoming more eco-friendly, and its longevity in application reduces the need for frequent replacements. As the wind energy sector strives for increased sustainability, the adoption of advanced materials like carbon fiber is a step towards minimizing the environmental footprint of renewable energy production.

Future Prospects and Industry Implications: The introduction of new carbon fiber for wind turbine blades represents a significant stride towards a more efficient and cost-effective future for wind energy. As technology continues to advance and economies of scale come into play, the integration of carbon fiber into wind turbines could become a standard practice. This innovation not only ensures a greener energy future but also highlights the pivotal role that materials science plays in driving positive change across industries.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries.

Resin, a viscous substance derived from natural or synthetic sources, acts as a fundamental building block in various industries. And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)

And of course you can add images or whatever you want here too.

Tabs are nothing new, but tabs that display inside your mega menu are pretty awesome :)